|

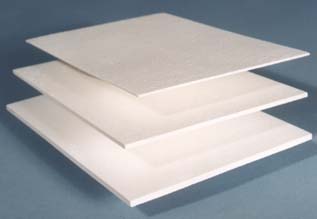

REFRACTORY SHEET BOARD TYPE RS-DD AND

RS-DR Document

in English

GENERAL INFORMATION

|

ZIRCAR Refractory Sheet Type RS-D는

고순도 알루미나 세라믹 섬유로 강화되어

얇은 시트형태로 공급되는 고순도

알루미나 제품으로써, 4가지 형태로

공급 가능한데, 몰더블 형태로 2종류, 견고한

시트형태로 2종류가 있습니다.

RS-DA와 RS-DM은

칼이나 가위로 쉽게 자를 수 있고, 스폰지나

솔 등을 사용해 양쪽 표면을 물로

적시고 신속하게 겹쳐진 부분을 압축하면

이음새를 만들 수 있습니다. 이러한

방법으로 2장 또는 그 이상을 겹치면

1/8"이상의 두께를 가진 제품을

만들 수 있습니다.

Refractory Sheet Type RS-DD는

다이 컷팅이나 가스켓 제작시 적합하고,

RS-DM을 다루는 것처럼 다시 물에

적셔 주조가 가능합니다.

RS-DR은

RS-DD제품처럼 자르거나 다룰 수 있고, RS-DD제품 보다 약하게 압축되어

있지만 더 견고한 제품으로, 열처리가

되어있어 물어 적셔도 견고함을 유지합니다.

RS-DR은

선열처리를 해서 유기 바인더를

제거한 시트제품으로 수분의 영향을

받지않고, 분말 금속 소결시 셋터나

칸막이로 사용합니다. |

TYPE RS-DA 는

고순도 플라스틱 몰더블 시트로

복잡한 모양을 주조하기에 적합합니다.

TYPE RS-DM 시트는

RS-DA제품보다 밀도가 높고,

다양하고 복잡합 모양을 제작할

수 있는 평평한 시트제품으로

금속 피복재나 스트립 히터등에

사용합니다.

RS-DD는 물에

적셔 주조할 수 있는 견고한 시트제품

입니다.

|

추천

용도

석면 시멘트 판재

대체품으로 사용 / 오븐 구조물로 사용

열 유도로 라이너

및 코일 장비에 사용 / 고온 가스켓팅에

사용

소결

및 열처리를 위한 형틀, 튜브, 쟁반, 보트

등에 사용

히팅 엘리먼트 보강재로

사용 / 내화 구조물의 단열재로

사용

스파우트, 낙수

받이, 주물 끝부분 등에서 비 다공성 물질을

다룰 때 사용

브레이징 분리기

및 정착물에 사용

뜨거운 용광로 보수유리를 녹이거나

담그기 위한 주형에 사용

PROPERTIES &

CHARACTERISTICS

|

Type |

DR |

DD |

DM |

DA |

|

Form |

Rigid sheet |

Rigid sheet2,3 |

Moldable sheet1,3 |

Plastic moldable

sheet1,3 |

|

Typical Composition, % |

|

|

|

|

|

Al2O3 |

90(dry) |

90(dry) |

90(dry) |

90(dry) |

|

SiO2 |

10(dry) |

10(dry) |

10(dry) |

10(dry) |

|

Organics |

nil |

nil |

<1 |

<1 |

|

Color |

White |

White |

White |

White |

|

Density(as supplied), pcf |

130 |

130 |

145 |

100 |

|

after drying @

100°C |

|

|

130 |

85 |

|

Thickness shrinkage, |

|

|

|

|

|

on drying at 100°C,

% |

|

|

10 |

25 |

|

Moisture, as supplied, % |

2 (4) |

3 (4) |

20 |

40 |

|

Maximum Use Temp. * °C(°F) |

1200 (2192) |

1200 (2192) |

1200 (2192) |

1200 (2192) |

|

Melting Point, °C(°F) |

1815 (3300) |

1815 (3300) |

1815 (3300) |

1815 (3300) |

|

Specific Heat, BTU/lb °F |

0.25 |

0.25 |

0.25 |

0.25 |

|

Modulus of Rupture, psi, |

|

as supplied |

3000 |

|

|

|

|

after firing 8 hrs. @

600°C |

|

|

|

490 |

|

Compressive Strength, psi |

|

|

|

|

|

as supplied @

5% compression |

10,000 |

|

|

|

|

at 8%

compression |

20,000 |

|

|

|

|

after firing 8 hrs. @

600°C, |

|

|

|

|

|

10% compression |

|

|

|

200 |

|

Firing Shrinkage, % |

|

|

|

|

|

after 1 hr. @

1000°C |

|

|

|

1 |

|

after 4 hrs. @

1000°C |

|

1 |

|

|

|

after 4 hrs. @

1200°C |

|

4 |

|

|

|

after 24 hrs. @

1200°C |

5 |

5 |

|

|

|

after 24 hrs. @

1400°C |

|

8 |

|

|

|

after 24 hrs. @

1500°C |

|

10 |

|

|

|

Thermal Expansion, in/in°C |

|

7x10-6 |

|

|

|

Softening Point, °C |

|

775 |

|

|

|

Arc Resistance, sec. |

360 |

|

|

|

|

Dielectric Strength, VPM |

530 |

|

|

|

|

Volume Resistivity, ohm-cm |

|

5x107 |

|

|

|

Thermal Conductivity, BTU/hr °F/in at mean

temp. = 600°C(estimated) |

|

|

4.5 |

|

|

3.8 |

1 Becomes rigid upon drying.

2 Can be made

moldable with addition of 10-20 wt% H2O.

3 Can be made

permanently rigid by heating to 300°C(570°F).

4 Depending on

humidity.

* Maximum Use Temperature is dependent on variables such as

stresses, both thermal and mechanical, and the chemical environment that

the sheet product experiences. Contact ZIRCAR Sales Office for more

information about the performance of these products in your

application.

STANDARD

AVAILABILITY

Prices effective

11-01-01

|

ZRCI ITEM # |

DESCRIPTION |

|

JS01 |

RS-DA 18" X 24" X .020" |

|

JS02 |

RS-DA 18" X 24" X .040" |

|

JS03 |

RS-DA 18" X 24" X .080" |

|

JS04 |

RS-DA 18" X 24" X .120" |

|

JS05 |

RS-DA 36" X 48" X .020" |

|

JS06 |

RS-DA 36" X 48" X .040" |

|

JS07 |

RS-DA 36" X 48" X .080" |

|

JS08 |

RS-DA 36" X 48" X .120" |

|

JS20 |

RS-DM 18" X 24" X .020" |

|

JS21 |

RS-DM 18" X 24" X .040" |

|

JS22 |

RS-DM 18" X 24" X .080" |

|

JS23 |

RS-DM 18" X 24" X .120" |

|

JS24 |

RS-DM 36" X 48" X .020" |

|

JS25 |

RS-DM 36" X 48" X .040" |

|

JS26 |

RS-DM 36" X 48" X .080" |

|

JS27 |

RS-DM 36" X 48" X .120" |

|

JS50 |

RS-DD 18" X 24" X .020" |

|

JS51 |

RS-DD 18" X 24" X .040" |

|

JS52 |

RS-DD 18" X 24" X .080" |

|

JS53 |

RS-DD 18" X 24" X .120" |

|

JS54 |

RS-DD 36" X 48" X .020" |

|

JS55 |

RS-DD 36" X 48" X .040" |

|

JS56 |

RS-DD 36" X 48" X .080" |

|

JS57 |

RS-DD 36" X 48" X .120" |

|

JS70 |

RS-DR 18" X 24" X .020" |

|

JS71 |

RS-DR 18" X 24" X .040" |

|

JS72 |

RS-DR 18" X 24" X .080" |

|

JS73 |

RS-DR 18" X 24" X .120" |

|

JS74 |

RS-DR 36" X 48" X .020" |

|

JS75 |

RS-DR 36" X 48" X .040" |

|

JS76 |

RS-DR 36" X 48" X .080" |

|

JS77 |

RS-DR 36" X 48" X .120" |

CUSTOM BOARDS AND SHAPES

- Our manufacturing process and machining

capabilities allow a wide variety of shapes to be made. Please contact

us with your special requirements.

|